Corrugated Fiberboard Plant

In StockCorrugated Fiberboard Plant – Fully Automatic 3/5/7 Ply Line for Premium Board Manufacturing

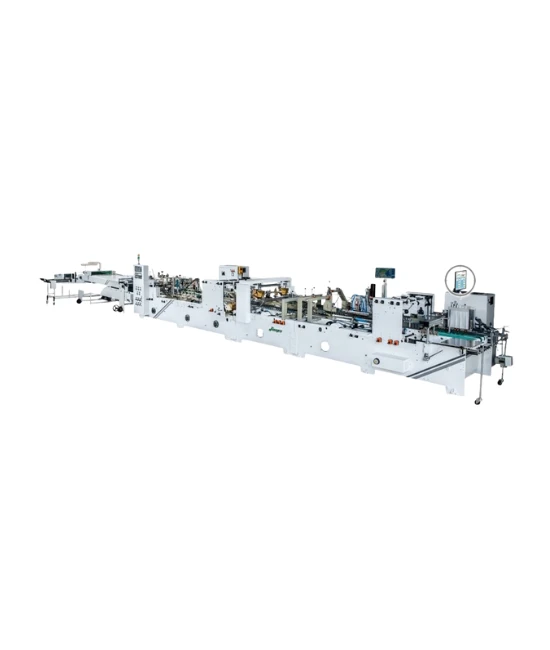

The Corrugated Fiberboard Plant is a fully automatic, high-capacity production line designed for manufacturing premium-quality 3, 5, and 7 ply corrugated fiberboard.

Ideal for box plants and packaging industries, this plant integrates all major processes including reel loading, paper preheating, single and double facer corrugation, gluing, drying, slitting, scoring, cutting, and stacking.

It supports various flute profiles like A, B, C, E, and combinations, offering flexibility for customized board types. Controlled via an advanced PLC system with an intuitive HMI touchscreen.

Corrugated Fiberboard Plant

In Stock

Corrugated Fiberboard Plant – Fully Automatic 3/5/7 Ply Line for Premium Board Manufacturing

The Corrugated Fiberboard Plant is a fully automatic, high-capacity production line designed for manufacturing premium-quality 3, 5, and 7 ply corrugated fiberboard.

Ideal for box plants and packaging industries, this plant integrates all major processes including reel loading, paper preheating, single and double facer corrugation, gluing, drying, slitting, scoring, cutting, and stacking.

It supports various flute profiles like A, B, C, E, and combinations, offering flexibility for customized board types. Controlled via an advanced PLC system with an intuitive HMI touchscreen.

Product Specification

Ply Support: 3 Ply / 5 Ply / 7 Ply

Working Width: 1400 mm to 2500 mm

Production Speed: Up to 300 meters per minute

Paper GSM Range: 90 – 440 GSM

Flute Types: A, B, C, E & combination profiles

Heating System: Steam or Thermic Fluid (1.2–1.5 MPa)

Mill Roll Stand: Hydraulic Shaftless with 2/3 Arms

Cut-Off Knife: NC Rotary Shear Knife

Stacking System: Pneumatic Jogger with Auto Counter

Control System: PLC with HMI Touchscreen Interface

Power Requirement: Approx. 250–350 HP

Line Length: 70 to 100 meters

Manpower Required: 8 to 10 Operator

Other Product

Request A Quotation