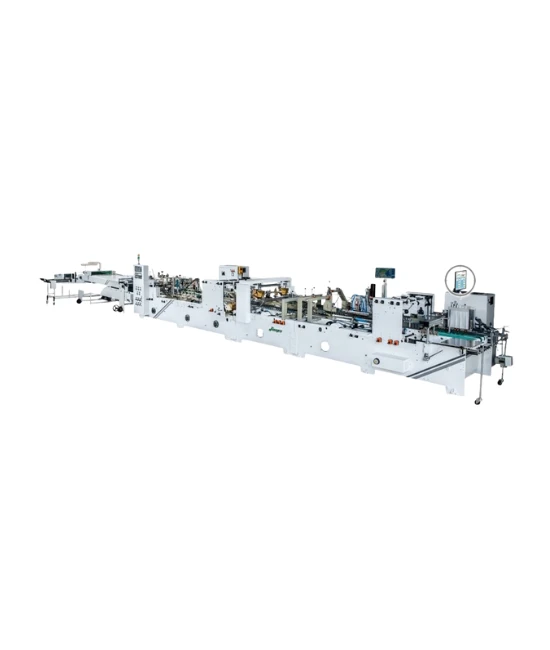

Automatic Corrugated Board Making Plant

In StockFully Automatic Corrugated Board Making Plant – High-Speed 3/5/7 Ply Line for Bulk Production

The Automatic Corrugated Board Making Plant is a highly efficient and fully integrated production line designed to manufacture high-quality corrugated boards in 3, 5, and 7-ply configurations.

This advanced plant features a series of precision-engineered machines, including Hydraulic Shaftless Mill Roll Stand, Preheater,

Single Facer, Overhead Bridge Conveyor, Gluer, Double Facer, Slitter Scorer, Cut-Off Unit, and Automatic Stacker. With production speed of up to 300 meters per minute, the line ensures consistent output.

Automatic Corrugated Board Making Plant

In Stock

Fully Automatic Corrugated Board Making Plant – High-Speed 3/5/7 Ply Line for Bulk Production

The Automatic Corrugated Board Making Plant is a highly efficient and fully integrated production line designed to manufacture high-quality corrugated boards in 3, 5, and 7-ply configurations.

This advanced plant features a series of precision-engineered machines, including Hydraulic Shaftless Mill Roll Stand, Preheater,

Single Facer, Overhead Bridge Conveyor, Gluer, Double Facer, Slitter Scorer, Cut-Off Unit, and Automatic Stacker. With production speed of up to 300 meters per minute, the line ensures consistent output.

Product Specification

Production Speed: Up to 300 meters/min

Board Layers: 3, 5, and 7 Ply

Working Widths Available: 1400 mm to 2500 mm

Paper GSM Range: 90 to 440 GSM

Flute Options: A, B, C, E (or combinations)

Control System: PLC with HMI Touch Screen

Heating System: Steam or Thermic Fluid (1.2–1.5 MPa Pressure)

Power Requirement: 200–300 HP (varies by configuration)

Operators Required: Typically 8–10

Line Length: Approx. 60–100 meters

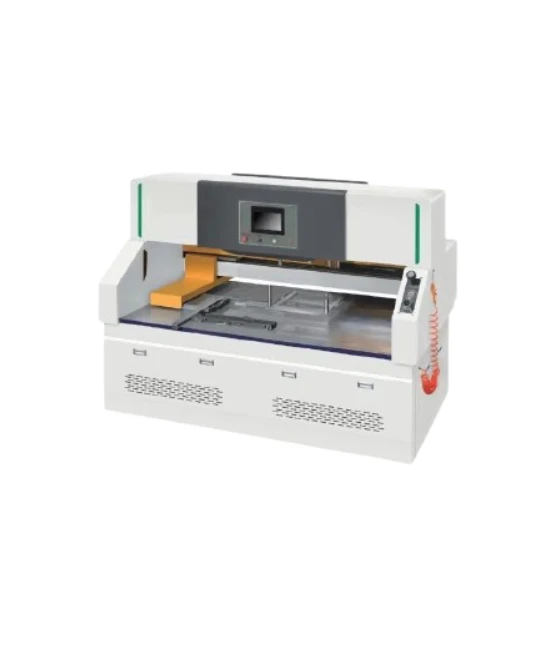

Other Product

Request A Quotation