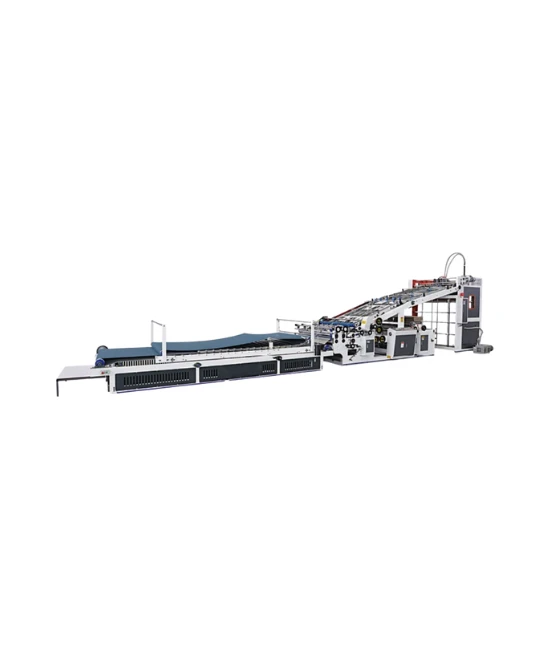

High Speed Single Facer Machine-Pneumatic Model

In StockHigh-Speed Single Facer Corrugation Machine – Flute Formation in Corrugated Board Production

The High-Speed Single Facer Machine – Pneumatic Model is engineered for efficient and accurate corrugated board production, offering exceptional performance at high speed.

This pneumatic model enables quick and smooth adjustment of the pressure roller, glue unit, and corrugation roller through air pressure controls, reducing downtime and enhancing productivity.

The machine features heavy-duty cast iron construction, tungsten carbide-coated corrugation rollers, and a motorized lubrication system for long-lasting durability and minimal maintenance.

High Speed Single Facer Machine-Pneumatic Model

In Stock

High-Speed Single Facer Corrugation Machine – Flute Formation in Corrugated Board Production

The High-Speed Single Facer Machine – Pneumatic Model is engineered for efficient and accurate corrugated board production, offering exceptional performance at high speed.

This pneumatic model enables quick and smooth adjustment of the pressure roller, glue unit, and corrugation roller through air pressure controls, reducing downtime and enhancing productivity.

The machine features heavy-duty cast iron construction, tungsten carbide-coated corrugation rollers, and a motorized lubrication system for long-lasting durability and minimal maintenance.

Product Specification

Vacuum suction type pulling cardboard with wind control device.

Glue roller and fixed roller are designed to groups guide way slippage load-unload, convenient and swift.

Flute roller and pressure roller adopt high temperature resistant lubrication grease.

Rolls Diameter is 235 mm and made from German made EN-19 Forged Material.

Pressure roll Diameter is 247 mm and this roll is made from CK-45 material.

Rolls are mounted on Bearings.

Machine Design speed 35m/min

S.S. Gum Tray (SS304 material used)

Circulating dam gum system.

Rewinding attachment with 1 no. rewinding Shafts

Automatic Lubrication Pump with Pipeline.

Working size: 42”

Other Product

Request A Quotation