Corrugated Box Making Plant

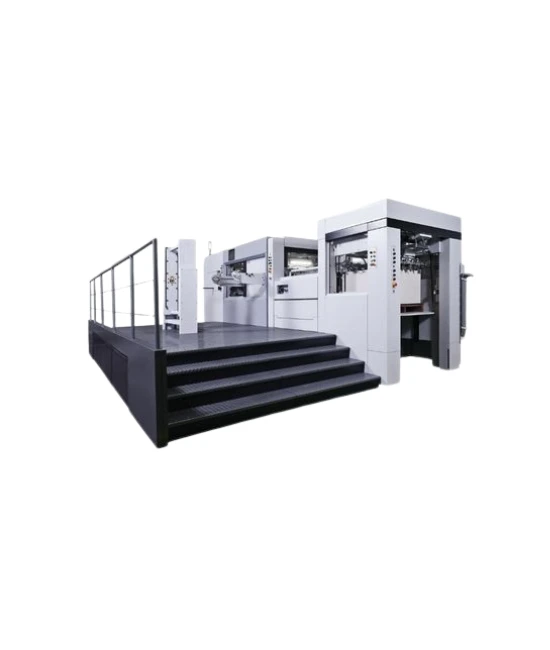

In StockCorrugated Box Making Plant – Fully Automatic 3/5/7 Ply High-Speed Carton Production Line

The Corrugated Box Making Plant is a fully automatic, high-performance system designed to manufacture 3-ply, 5-ply, and 7-ply corrugated boxes with maximum efficiency and accuracy.

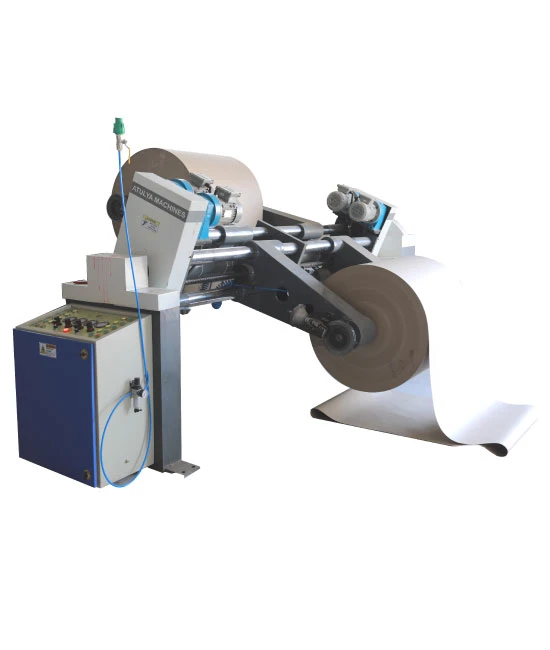

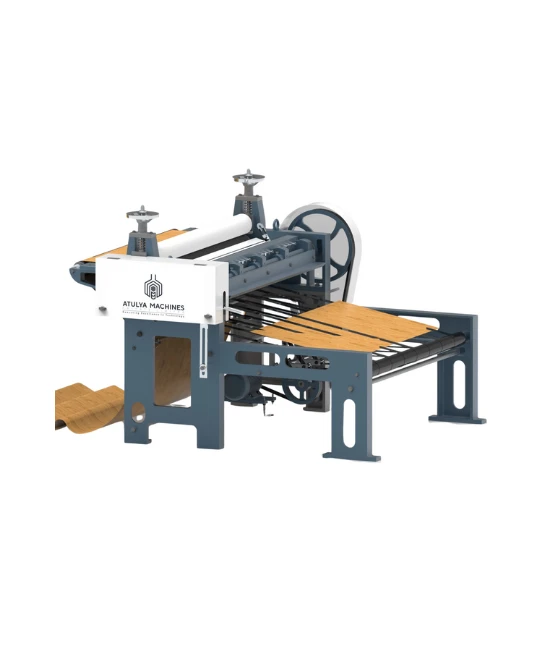

Engineered for industrial-scale packaging operations, this plant includes all key components such as Hydraulic Shaftless Mill Roll Stand, Preheater, Single Facer, Bridge Conveyor, Gluer, Double Facer, Slitter Scorer, NC Cut-Off, and Automatic Stacker.

Corrugated Box Making Plant

In Stock

Corrugated Box Making Plant – Fully Automatic 3/5/7 Ply High-Speed Carton Production Line

The Corrugated Box Making Plant is a fully automatic, high-performance system designed to manufacture 3-ply, 5-ply, and 7-ply corrugated boxes with maximum efficiency and accuracy.

Engineered for industrial-scale packaging operations, this plant includes all key components such as Hydraulic Shaftless Mill Roll Stand, Preheater, Single Facer, Bridge Conveyor, Gluer, Double Facer, Slitter Scorer, NC Cut-Off, and Automatic Stacker.

Product Specification

Board Types Supported: 3 Ply / 5 Ply / 7 Ply

Production Speed: Up to 300 meters per minute

Working Widths: 1400 mm to 2500 mm

Paper GSM Range: 90 – 440 GSM

Flute Profiles: A, B, C, E, and combination flutes

Mill Roll Stand: Hydraulic Shaftless (2 or 3 Arms)

Heating System: Steam or Thermic Fluid (1.2–1.5 MPa)

Slitter Scorer: Pneumatic Knife with Servo Control

Cut-Off Knife: Rotary Shear, Servo Driven

Auto Stacker: Pneumatic Jogging & Box Counting System

Control Panel: PLC with HMI Touchscreen

Power Requirement: 200–350 HP (depending on configuration)

Line Length: 60 to 100 meters

Operator Requirement: 8 to 10 Skilled Personnel

Other Product

Request A Quotation