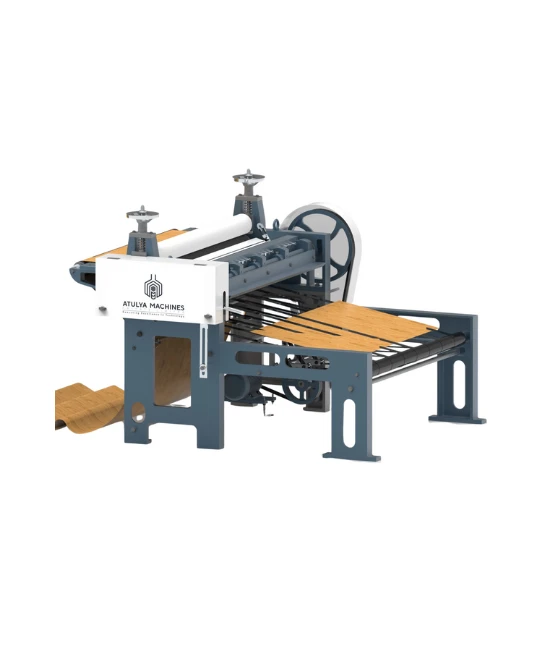

Automatic Corrugated Box Making Line

In StockHigh-Speed Automatic Corrugated Box Making Line – Efficient Production up to 250 Boxes/Min

The Automatic Corrugated Box Making Line is a state-of-the-art solution designed for high-efficiency production of corrugated boxes. Integrating advanced automation, this line streamlines the entire manufacturing process—from raw paper feeding to final box stacking.

Its modular design includes components such as hydraulic mill roll stands, preheaters, single facers, gluing machines, double facers, slitter scorers, cut-off machines, and stackers. Equipped with PLC control systems and HMI interfaces, it ensures precise operation, quick changeovers, and minimal downtime.

Automatic Corrugated Box Making Line

In Stock

High-Speed Automatic Corrugated Box Making Line – Efficient Production up to 250 Boxes/Min

The Automatic Corrugated Box Making Line is a state-of-the-art solution designed for high-efficiency production of corrugated boxes. Integrating advanced automation, this line streamlines the entire manufacturing process—from raw paper feeding to final box stacking.

Its modular design includes components such as hydraulic mill roll stands, preheaters, single facers, gluing machines, double facers, slitter scorers, cut-off machines, and stackers. Equipped with PLC control systems and HMI interfaces, it ensures precise operation, quick changeovers, and minimal downtime.

Product Specification

Production Speed: Up to 250 boxes per minute

Board Layers: 3, 5, and 7-ply compatibility

Effective Width: 1400mm to 2500mm

Design Speed: Up to 300 meters per minute

Paper Grades: Liner: 110–400 gsm; Medium: 90–180 gsm

Flute Types: A, B, C, E, and combinations thereof

Power Requirement: Approximately 150–300 kW, depending on configuration

Steam Pressure: 1.2 MPa; Consumption: ~3000–3600 kg/h

Air Pressure: 0.4–0.8 MPa

Machine Length: Approximately 60–100 meters

Control System: Advanced PLC with HMI touch screen

Operators Required: Typically 9 persons

Other Product

Request A Quotation